Wafer Polishing Characteristics

Polishing pads are classified as either non-woven and woven. Woven polishing pads are fiber woven textile cloths, whereas, non-woven pads are polymetric pads which typically have a porous structure.

NANOFINISH Corporation offers wide selection of woven and non-woven polishing pads for industrial polishing operations. Our woven products include our low napped POLYPAD pad, as well as our high napped MICROPAD.

The non-woven products include our PC urethane impregnated polishing pads as well as our more chemically resistant BLACKCHEM 2 polishing pad.

NANOFINISH Corporation offers a selection of felt polishing pads comparable to the POLITEX (BLACKCHEM 2), SUBA 500, SUBA V, SUBA IV, GS, SUBA X and natural wool polishing pads that are found in the industrial polishing market today.

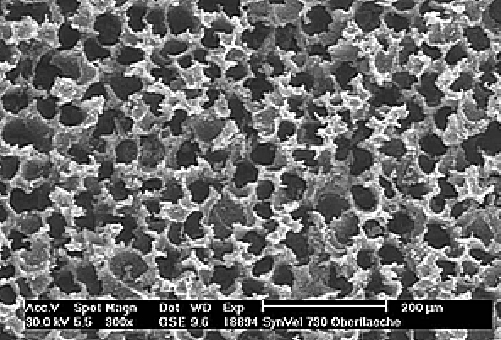

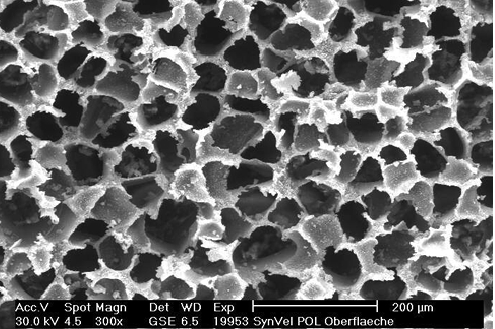

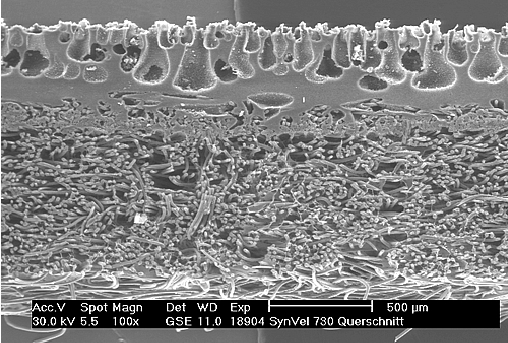

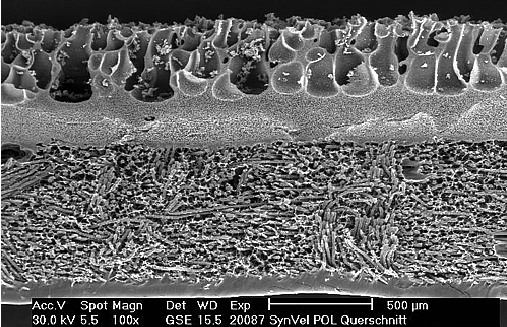

BLACKCHEM 2BLACKCHEM 2 is a replacement polishing pad for the POLITEX polishing pad (see comparision table below). Its main application is for CMP polishing with alumina or colloidal silica. The BLACKCHEM 2 also has a very similar and porous structure as the POLITEX pad.

|

Properties |

PACE |

RODEL |

|

Thickness in mm |

1.369 |

1.471 |

|

Weight g/m2 |

583.1 |

582.6 |

|

Hardness Shore A |

66 |

61 |

|

Compressibiity in % |

|

|

|

Surface resistance in mg |

|

|

|

Pores volumes of open pores in % |

68.6 |

78.1 |

|

Average pore size in um |

40.6 |

55 |

|

Wetting angle (against water) |

|

|

|

|

| Pore structure for BLACKCHEM 2 (SEM 300X). | Pore structure for POLITEX (SEM 300X). |

|

|

| Cross section for BLACKCHEM 2 (SEM 100X). | Cross section for POLITEX (SEM 100X). |

PC Impregnated Felt Polishing Pads

The PC series of polishing pads are replacement polishing pads for the SUBA series of polishing pads (see comparision table below). The main polishing applications for these urethane impregnated polishing pads are for glass, ceramics, precision optics and other materials where surface finish is critical.

|

NANOFINISH |

Replaces |

Specific Gravity |

Durometer Hardness |

Thickness |

Max size |

|

PC80 |

SUBA 500 |

0.58 |

>C80 |

0.050" - 1" |

39.5" x 39.5" |

|

PC60 |

SUBA V |

0.40 |

>C60 |

0.050" - 1" |

39.5" x 39.5" |

|

PC40 |

SUBA IV |

0.34 |

C40 |

0.090" - 1" |

53" x 53" |

|

PC55-LD |

SUBA X |

0.32 |

C55 |

0.050" - 1" |

39.5" x 39.5" |

|

PC55-HD |

SUBA X |

0.42 |

C55 |

0.050" - 1" |

39.5" x 39.5" |

|

PC20 |

Natural wool |

0.31 |

C20 |

1/8" - 1" |

53" x 53" |

|

|

|

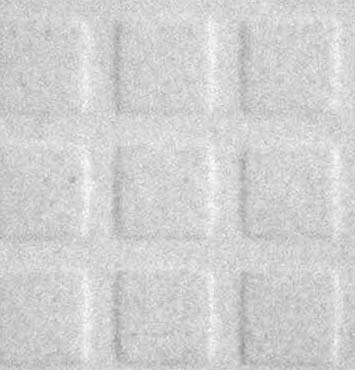

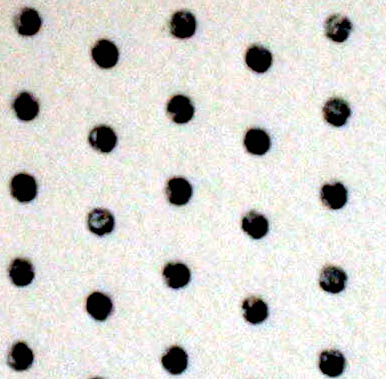

PC60 Embossed Polishing Pad |

PC60 Perforated Polishing Pad |

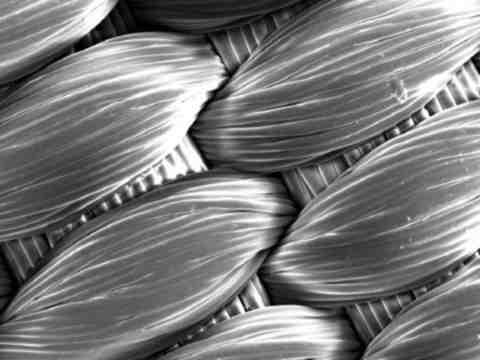

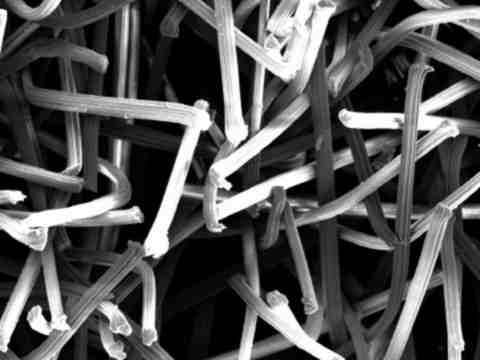

Woven Polishing Pads

The POLYPAD polishing pads have a low napped woven polishing design as shown below. This pads is very durable and is an excellent polishing pad for intermediate sized diamond, silicon carbide, ceria, or alumina polishing slurries. The MICROPAD final polishing pad is a high napped or flocked polishing pad. It produces a relatively gentle polishing action and is very useful for polishing metals and other soft materials.

|

|

|

DACRON and POLYPAD Woven Polishing Pads |

MICROPAD High Napped Polishing Pad |

Recommended Application

The following is a list of recommendations to maximize the performance of the polishing or lapping operations.

- Match the polishing pad characteristics to the material to be polished

- Charge the abrasive to the polishing surface

- Use a polishing lubricant designed to remove polishing or grinding swarf. This can significantly increase the life and performance of the polishing surface