Polishing Lubricant Characteristics

Lapping lubricants for MR and GMR thin film magnetic heads must be capable of reducing pole-tip and alumina recession while eliminating the corrosion of exotic alloys. An ideal lapping lubricant for MR and GMR magnetic heads should be enviromentally safe, ehance the performance of the lapping surface and easily cleaned with conventional polar solvents or water based cleaning solutions.

- Higher lapping rates (3-5X)

- Greater lapping machines throughput

- Evironmentally safe, non hazardous waste material

- Longer plate life (10-50X)

- More consistent lapping performance

- Reduced lapping costs

Lapping lubricants for magnetic sliders can dramatically affect surface finish, PTR, smearing, sensor corrosion, lapping removal rates and the lapping plate life. The ideal lapping lubricant is easy to clean as well as it provides a cleaning action to either the lapping plate or the lapping film surface.

|

LUBRICANT |

Plate Cleaning |

Cut rate Enhancer |

Contains organic corrosion inhibitor |

Rough Lapping |

Finish Lapping |

Environmentally friendly |

|

POLYLUBE H9 |

√√ |

√ |

√ |

√ |

|

|

|

DIALUBE 9G |

|

√ |

√ |

√ |

√ |

|

|

DIALUBE 3000 |

√ |

√ |

Promotes pH passivation |

√ |

|

√ |

| L7000 | √ | √ | ||||

| L7500 (higher viscosity) | √ | √ |

Recommended Applications:

|

LUBRICANT |

Application |

| DIALUBE 7000 | -Direct lower cost replacement for ENGIS L6037 lapping lubricant. |

| DIALUBE 7500 | -Higher viscosity (25 cps or greater) for eliminating lapping vibration with present state of the art lapping machines used for Pico sized magnetic heads. |

|

POLYLUBE H9 |

-Recommended for use at the beginning of the lapping cycle.

|

|

DIALUBE 9G |

-Recommended as a replacement for the most common ethylene glycol based lubricants. Promotes higher cut rates and longer plate life with final lapping parameters similar to existing lapping lubes. |

|

DIALUBE 3000 |

-Recommended for extending the cutting life of diamond lapping films

|

| DIALUBE OL-3000 | -Oil based lubricant for non-aqueous systems |

GRINDING SWARF REMOVAL

Suspending the grinding swarf is the key to increasing cut rates and for more stable and improved lapping plate life. The basic concept is that the lubricant has a strong affinity to the grinding swarf and the lapping plate or lapping film. An additional characteristic of the lubricant is that it produces a highly charged surface coating on the lapping plate or swarf; the result is that the grinding swarf has a strong repulsion to the lapping plate and other grinding particles. This strong replusion keeps the grinding swarf from settling and packing into the grinding surface, thus keeping the diamond grinding particle open for enhanced grinding.

DIALUBE 7000 and 7500

The DIALUBE 7000 and 7500 lapping lubricants are ethylene glycol based lapping lubricants which are direct lower cost replacements for the Engis L6037 lubricant. The DIALUBE 7000 lubricant has similar viscosity, surface tension and contact angle or wetability characteristics the the Engis L6037 lubricant. The DIALUBE 7500 lube has similar surface tension and wetability, however has a higher viscosity which is required with the more modern Vecco Advanced Imaging lapping machines. Table I shows a comparison table for the various DIALUBE and Engis lapping lubricants.

POLYLUBE H9 LAPPING LUBE

The POLYLUBE™ H9 lapping lube is a specifically formulated cleaning lubricant for lapping GMR and TMR magnetic heads. It is also a non-ethylene glycol formulation, which is a biodegradable and environmentally safe, thus eliminating costly disposal fees. The POLYLUBE™ H9 lapping lube is an ideal lubricant for applying at the beginning of the lapping cycle to clean the swarf build-up off the lapping plate. This swarf removal increases the lapping rates by 3-5 times and significantly extends plate life. Additional improvements include: improved lapping consistency, more consistent PTR and alumina recession, less smearing and improved surface finishes.

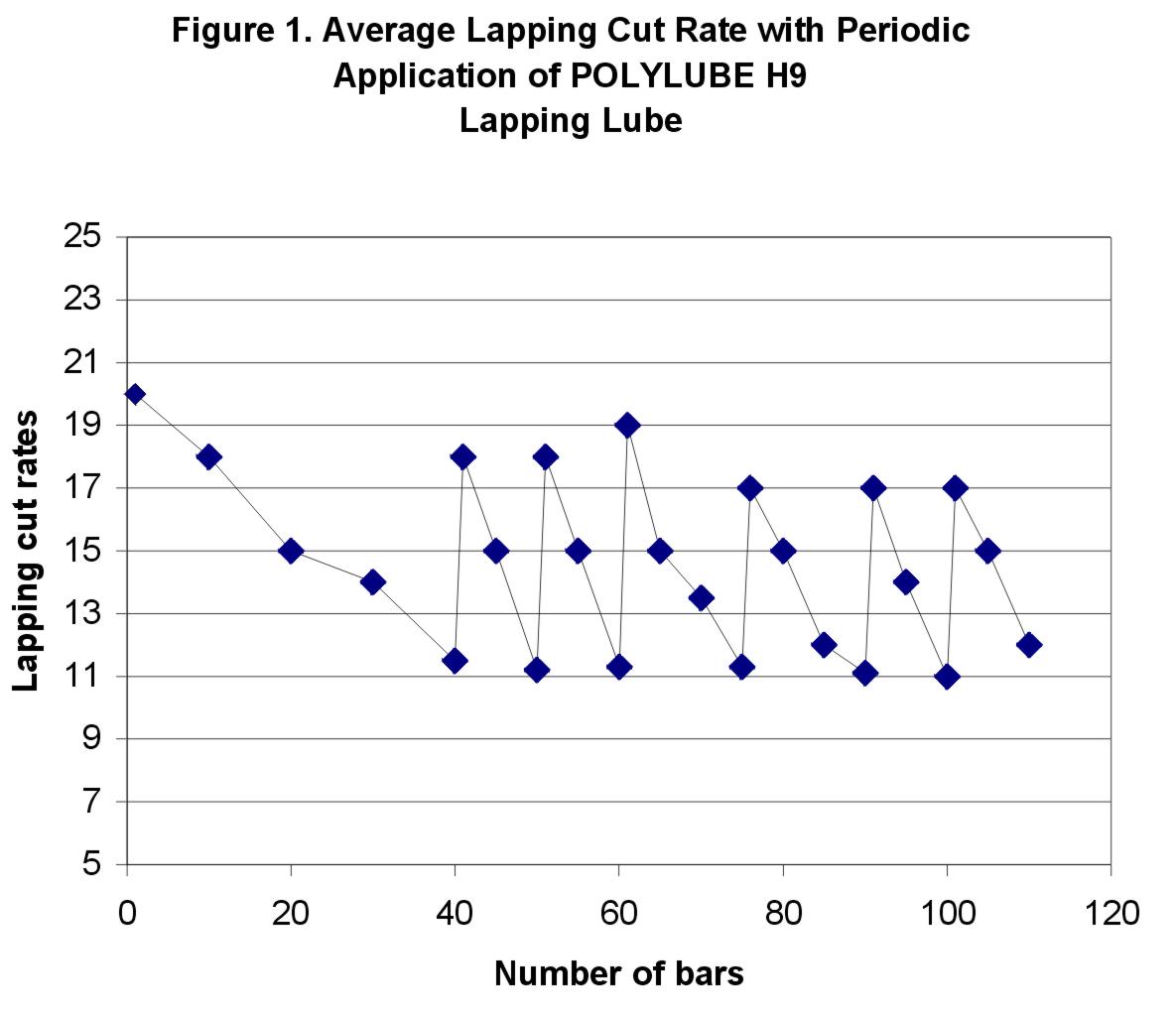

POLYLUBE™ H9 lapping plate

cleaning lube has been demonstrated to reactivate or restore the lapping rate of tin alloy lapping plates. Figure 1 shows the effect of lapping plate cut rate as the POLYLUBE™ H9 cleaning lube was applied after the cut rate dropped below 12 micoinches per minute. Figure 1 shows that the use of POLYLUBE™ H9 increased the cut rate by as much as 80%. This cycle repeated itself and significantly increased the lapping plate performance.

|

|

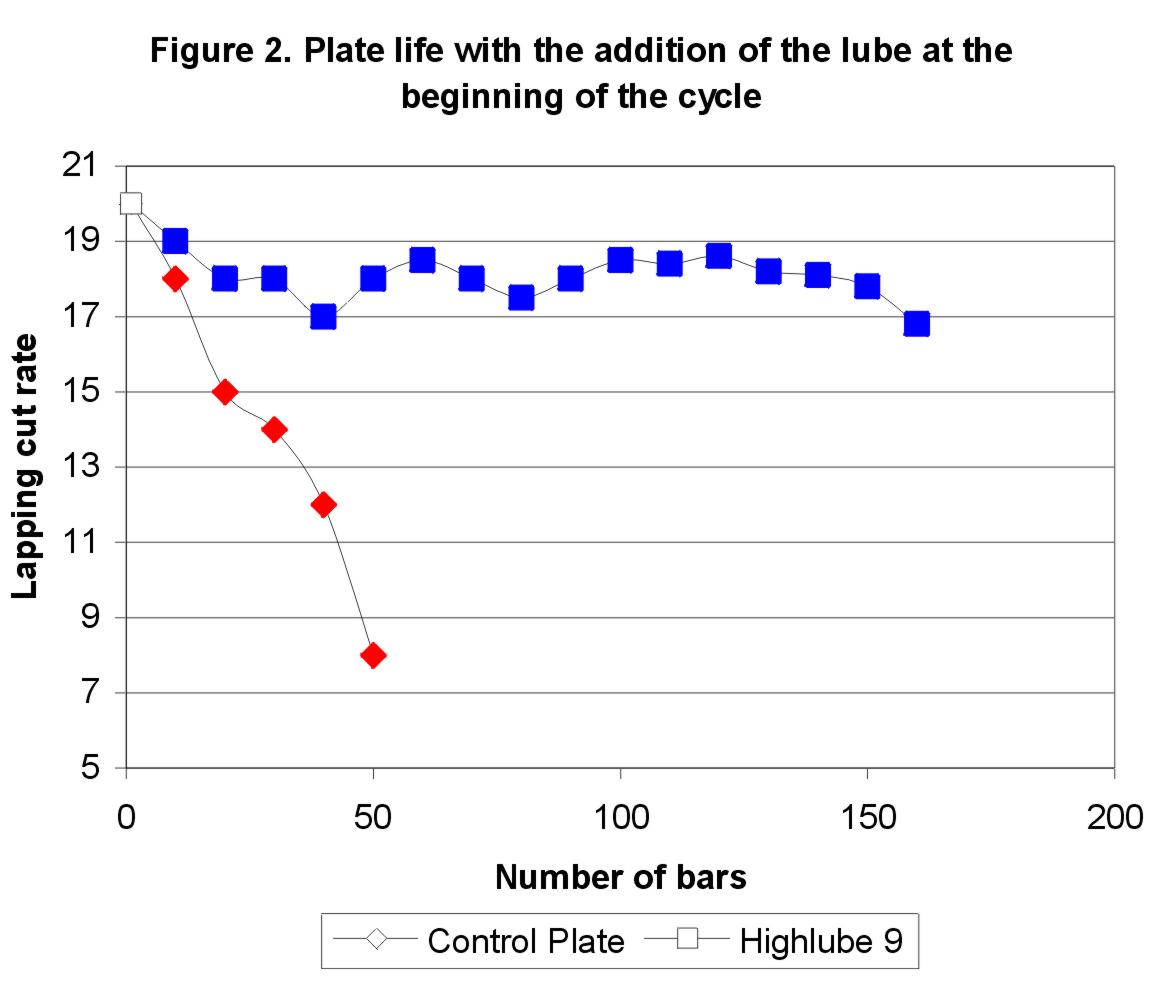

Figure 2 shows the effect of

adding the POLYLUBE™ H9 at the

beginning of each lapping cycle. The result shows that lapping plate cut rate is very stable and promotes for more consistent and stable lapping.