CMP Polishing

Chemical Mechanical Polishing (CMP) is a technique which utilizes both a mechanical abrasive with a chemical surface reactant with the material surface. CMP polishing is very useful for minimizing both surface and subsurface damage in ceramics, semiconductor materials, and soft metals. The most common CMP abrasives are colloidal silica and alumina at either a low or high pH's. In addition to pH, the solution chemistry oxidation or reduction potential can significantly enhance the chemical contribution.

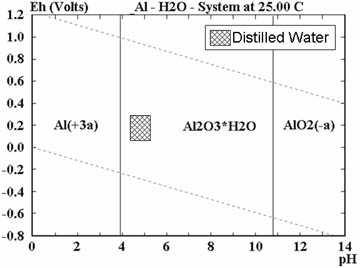

A useful tool for initially evaluating a particle materials ability to be polished by CMP processes is with the use of Pourbaix diagrams. Pourbaix diagrams are thermodynamically derived stability diagrams for various pH and oxidation potentials. Figure 1 shows the Pourbaix diagram for the alumina or aluminum-water system. The Pourbaix diagram shows that at intermediate pH values ranging from 4-10 alumina is the most stable species; however, at pH values below 4, Al(+3) is more thermodynamically stable and at pH values above 10, AlO(-) is the most stable species. This would indicate that CMP polishing of an alumina ceramic would be possible at either low or high pH values. Note that the Pourbaix diagrams are useful in determining the most thermodynamically stable species, it does not provide any kinetic or dissolution rate information. The actual dissolution rates can be determined with more sophisticated electrochemical methods, although in practice the effectiveness of CMP polishing is determined by experiemental techniques.

|

Colloidal Silica Abrasives for Ceramics

Colloidal silica polishing suspensions are unique because they provide both a dispersing action as well as a chemical mechanical polishihg (CMP) action. It is effective as an additive for the intermediate diamond polishing of metals and is also the best plishing abrasive for eliminating subsurface and surface damage in ceramics because of its CMP polishing action.

Colloidal silica is a very unique polishing suspension because it provides a chemical mechanical polishing (CMP) action for materials such as ceramics, composites and soft metals. Colloidal silica has particle size distribution between 0.05 um and 0.07 um and is stabilized at alkaline pH values (typically >9.5).

Ceramics and Minerals - At higher pH values colloidal silica is held in nearly perfect suspension by the electrochemical repulsive forces of the fine particles themselves. This chemical balance electrochemcially attacks the surface of a ceramic or mineral surface to form a thin reacted layer on the specimen surface. This reacted layer can then be removed via the mechanical action of the polishing cloth or another abrasive (e.g. diamond). Polishing rates and surface finishes are significantly better for ceramics and minerals as compared with straight mechanical abrasives such as diamond. Thus the highest removal rates and the most reliable action for removing both surface and subsurface damage on ceramics and minerals is via chemical mechanical polishing with colloidal silica.

As with other exothermic chemical reactions the chemical contribution can be enhanced by increasing the temperature of the polishing action. This can be accomplished by increasing the polishing pressure which increases the friction between the polishing cloth, colloidal silica and the specimen.

Cleaning of the surface is best accomplished by running water on the surface for the final 10-15 seconds of the polishing cycle and then immediately rinsing the specimen surface with water. This allows the cloth to mechanically remove the reacted layer and any residual colloidal silica.

Application of Colloidal Silica- The most efficient application is to initially wet the polishing cloth with SIAMAT Colloidal Silica and then to slowly drip or spray the suspension onto the polishing cloth

- It is recommended that water be applied continuously to the polishing cloth for 10-15 seconds prior to completion of the polishing step. This aids in removing the fine particles which may be electrostatically attracted to the specimen surface.

|

Colloidal Silica (0.05 micron) |

||||

|

Description |

Quantity |

Catalog Number |

||

|

SIAMAT Colloidal Silica |

1 gallon |

SI-100A-128 |

||

|

SIAMAT Colloidal Silica |

5 gallons |

SI-100A-640 |

||

|

SIAMAT Colloidal Silica |

55 gallons |

SI-100A-5G |

||

|

Colloidal Silica (0.02 micron) |

||||

|

Description |

Quantity |

Catalog Number |

||

|

SIAMAT2 Colloidal Silica |

1 gallon |

SI2-100A-128 |

||

|

SIAMAT2 Colloidal Silica |

5 gallons |

SI2-100A-640 |

||

|

SIAMAT2 Colloidal Silica |

55 gallons |

SI2-100A-5G |

||