Polycrystalline diamond abrasives are manufacturered by transforming graphite into diamond via a high temperature and high pressure explosion process. The resulting particle is comprised of numerous microcrystallites bonded together. Particle sizing is accomplished by milling or grinding the aggregate particle.

|

|

|

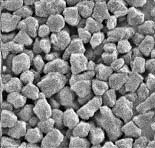

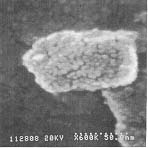

| HSEM (High Resolution Scanning Electronic Microscope) picture of our powder size 0.05-.2 mcm at 10,000 times magnification. | HSEM (High Resolution Scanning Electronic Microscope) picture of our powder size 0.05-.2 mcm at 600,000 times magnification. |

Polycrystalline diamond as compared to synthetic and natural monocrystalline diamond provides better surface finishes and higher removal rates for metallographic specimen preparation. The features and advantages of polycrystalline diamond include the following:

- Higher cutting rates

- Very uniform surface finish

- More uniform particle size distribution

- Higher removal rates (self sharpening abrasives)

- Harder/tougher particles

- Blocky shaped

- Hexagonal microcrystallites (equally hard in all directions)

- Extremely rough surface (more cutting points)

- Surface area 300% greater than monocrystalline diamond

- No abrasion-resistant directionality (abrasion independent of particle orientation)

Polycrystalline Diamond Technical data

|

Appearance (dry state): |

Color |

Gray |

|

Chemical composition: |

Carbon |

99 % |

|

Hydrogen |

< 1 % |

|

|

Nitrogen |

< 1% |

|

|

Oxygen |

< 1% |

|

|

Physical data: |

Particle sizes available: |

0.05-0.15; 0.05-0.2; 0-0.25; 0-0.5; 0.5-1.0; 0-1.0; 0.5-1.5; 1-2; 0-2; 1-3; 0-10 um. |

|

Specific gravity: |

3.451 |

|

|

Friability index: |

75-80% |

|

|

Structure: |

polycrystalline, with the block size under 0.1 um |

|

|

Decomposition |

decomposes with a heat over 500°C |

|

|

Electrical conductivity: |

non-conductive |

Recommended Application

The following is a list of recommendations to maximize the performance of the polishing or lapping operations.

- Match the polishing pad characteristics to the material to be polished

- Charge diamond at higher pressure than the lapping process

- Use a polishing lubricant designed to remove polishing or grinding swarf. This can significantly increase the life and performance of the polishing surface