Grinding and Polishing Damaged DVD and CD's

For disks with deeper scratching and damage, fine grit silicon carbide abrasives are recommended prior to polishing with alumina polishing papers. Silicon carbide (SiC) is a manufactured abrasive produced by a high temperature reaction between silica and carbon. It has a hexagonal-rhombohedral crystal structure and has a hardness of approximately 2500 HV. It is an ideal abrasive for cutting and grinding because of its hardness and sharp edges. It is also somewhat brittle, and therefore it cleaves easily to produce sharp new edges (self sharpening).

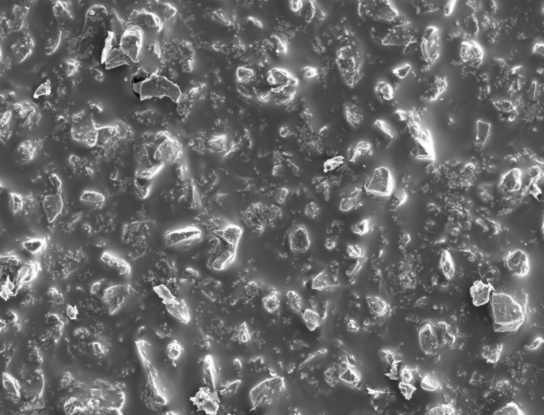

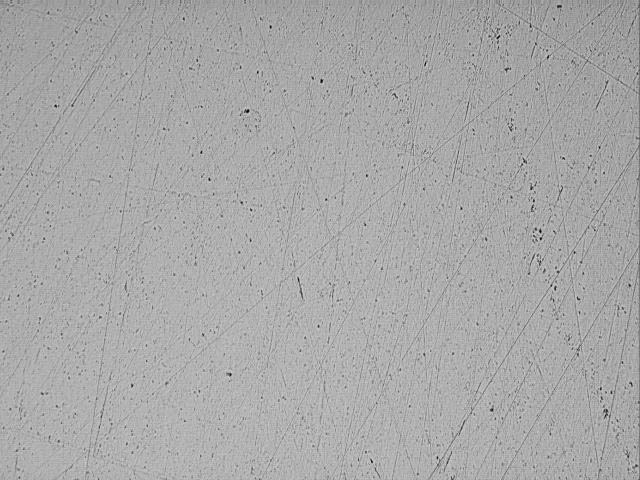

Special 800, 1000 or 1200 grit SiC abrasive papers are manufactured to produce a very uniform and consistent surface finish on polycarbonate disks. This manufacturing process differs from the electrostatically produced abrasive papers which are commonly used for grinding. Fiber optic grinding papers and films are produced by a slurry coat process which produces a more uniform surface finish. Slurry coated fiber optic grinding papers and films are an excellent abrasive for removing the deeper scratches in DVD / CD disks. Figure 1 to the left shows an 800 grit SiC carbide paper at high magnification. Fgure 2a and 2b show the surface finish produced and surface roughness produced for 800 and 1200 grit SiC abrasive papers.

Special 800, 1000 or 1200 grit SiC abrasive papers are manufactured to produce a very uniform and consistent surface finish on polycarbonate disks. This manufacturing process differs from the electrostatically produced abrasive papers which are commonly used for grinding. Fiber optic grinding papers and films are produced by a slurry coat process which produces a more uniform surface finish. Slurry coated fiber optic grinding papers and films are an excellent abrasive for removing the deeper scratches in DVD / CD disks. Figure 1 to the left shows an 800 grit SiC carbide paper at high magnification. Fgure 2a and 2b show the surface finish produced and surface roughness produced for 800 and 1200 grit SiC abrasive papers.

|

|

|

| Figure 2a. 800 girt SiC Surface Finish on polycarbonate plastics (mag. 100X) | Figure 2b. 1200 grit SiC Surface Finish on polycarbonate plastics (mag. 100X) |

SiC Abrasive Papers

| SiC Abrasive paper | Diameter | Catalog Number (plain backed) |

Catalog Number (Adhesive backed) |

| 800 grit | 5.5-inch | SIC-2105-800 | SIC-800-P5 |

| 1000 grit | 5.5-inch | SIC-2105-1000 | SIC-1000-P5 |

| 1200 grit | 5.5-inch | SIC-2105-1200 | SIC-1200-P5 |