Lapping Plate Preparation

The following diagram shows a typical lapping plate preparation procedure for flattening, truing, texturzing and charging the lapping plates used for lapping magnetic read-write hard drive and tape heads.

Lapping Plate Mounting Adhesive

The LP-1000 is a thermoplastic acrylic foam mounting adhesive is a fast and easy mounting and demounting adhesive for adhering lapping plates to the lapping machine base plate. The lapping plate is easily mounted by pre-wetting the adhesive with IPA which allows the lapping plate to be positioned on the base plate prior to curing. Curing time is approximately 15 minutes for a rigid bond, with full curing occurring in 2-4 hours. To remove the expended lapping plate, heat the lapping plate and base to approximately 150 degrees Celcius in order to soften the adhesive and peal off the used lapping platelapping plate.

Truing Abrasives

The process of truing the lapping plate is required becasue present machining technology does not produce a lapping plate flat enough for lapping the magnetic heads. The most common truing process uses an alumina lapping film.

Texturizing

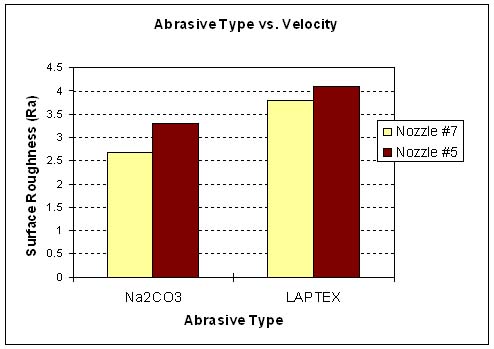

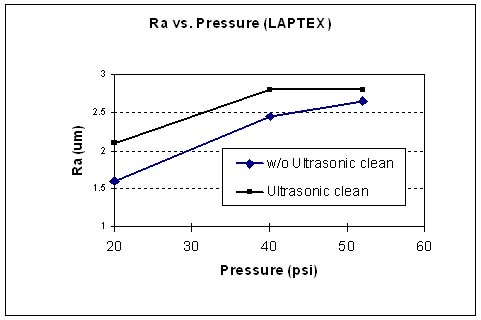

Lapping plate texturizing is required so that the diamond abrasives embed more effectively into the lapping plate. The most common technique is to use a soft abrasive blasting process. Sodium bicarbonate (Na2CO3) has been used for a number of year because it is soft and mostly soluble in water. In addition to sodium bicarbonate, the LAPTEX blasting media is a harder and more water soluble abrasive. The LAPTEX blasting media also has a more uniforn particle size distribution.

|

|

Charging pads

For more consistent charging boron carbide charging tools provide longer life and more efficient diamond charging.